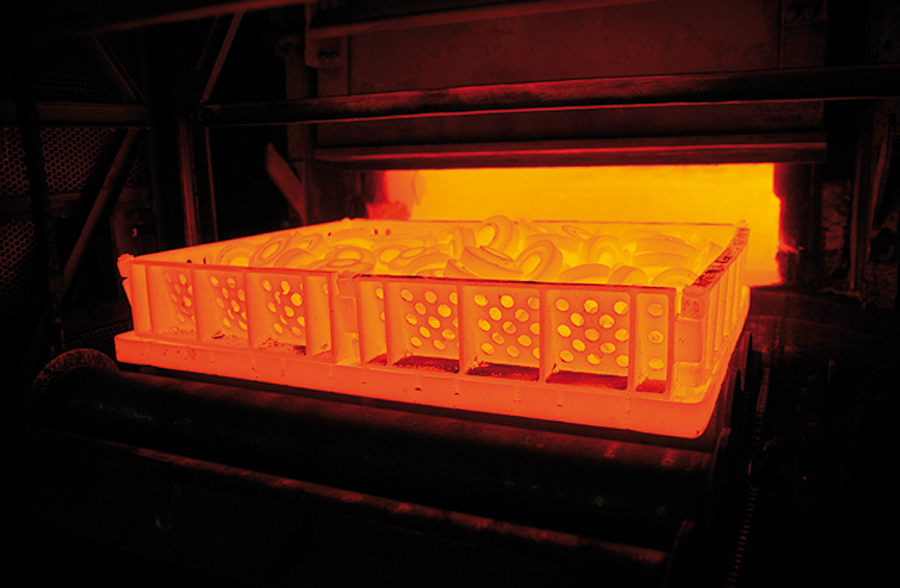

Process of Heat Treatment

The process of heat treatment generally includes three processes of heating, heat preservation and cooling, and sometimes there are only two processes of heating and cooling. These processes are interconnected and uninterrupted.

Annealing, normalizing, quenching, and tempering are the “four fires” in the overall heat treatment. Among them, quenching and tempering are closely related, and are often used together.

Quenching can improve the hardness and wear resistance of the material, but the material will become brittle, and the toughness and plasticity will also deteriorate.

The purpose of annealing is to reduce the hardness of the material, improve the performance of material forming and cutting, eliminate internal stress, and prevent material deformation and cracking

Normalizing is to refine the material structure, improve the cutting performance of the material, and can also be used as the final heat treatment for less demanding parts

Tempering is to reduce the stress and brittleness of the material

Therefore, tempering is generally used at the same time as quenching.

The so-called quenching and tempering treatment is quenching and high temperature tempering, so that the material has both strength, hardness and certain plasticity and toughness.

Ningbo Tianhui Machine is a professional CNC Machining factory and can provide the heat treatment for the custom metal parts.

If you have this requirement, please contact us!

Leave a Reply

Want to join the discussion?Feel free to contribute!