CNC Drilling Services

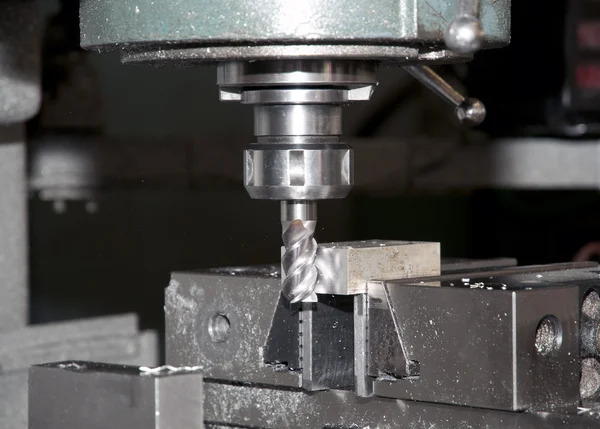

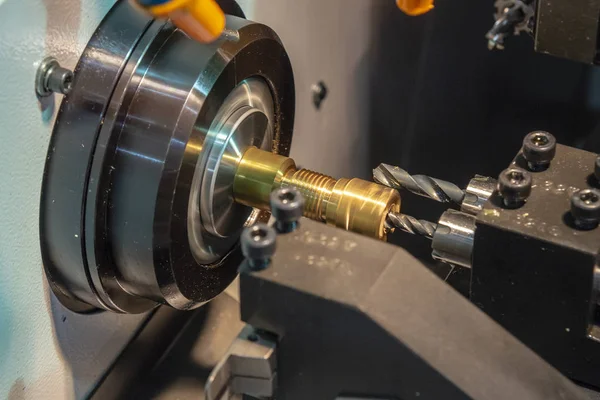

CNC drilling services produce precise round holes or threaded defects, typically for machine screws and bolts. Drilling can produce CNC drilled parts in metal, hard plastics, wood, and most other rigid materials. There are several types of drilling machines available for CNC, including these: upright, table, and radial. When in use, the step-by-step process of CNC drilling includes:

1. The operator uploads and accesses a computer-aided design (CAD) or computer-aided manufacturing (CAM) file.

2. The operator mounts the appropriate drill bit and secures the designated material to the table.

3. The operator initiates the drilling process via the control panel or interface.

4. The spindle is lowered, and the appropriate hole size and diameter is drilled.

5. If the customer has additional requirements or needs, the part is machined.

6. The part is packaged and shipped to the customer’s doorstep.